Manuals and Master Courses 2024 “Elastomers & Rubber Applications”

- Home Articles & Publications

- Manuals and Master Courses 2024 “Elastomers & Rubber Applications”

Manuals and Master Courses 2024 “Elastomers & Rubber Applications”

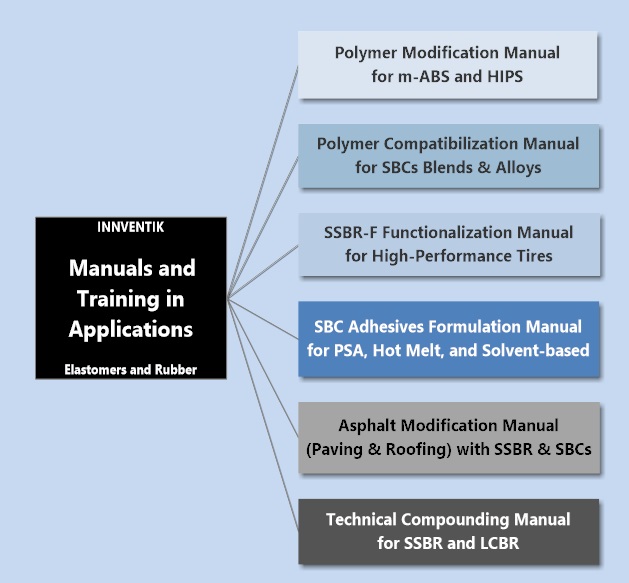

Madrid, March 11, 2024. Innventik offers Manuals and Master Courses in Elastomers and Rubber Applications. The applications addressed include (a) Polymer Modification for mass ABS and High Impact Polystyrene (HIPS), (b) Polymer Compatibilization for SBCs Blends and Alloys, (c) SBC Adhesive Formulations for PSA, Hot Melt, and Solvent-Base. Asphalt and Bitumen Modification (Paving and Roofing9) with SSBR and SBCs. (d) Technical Compounding Manual for SSBR and LCBR.

The Manuals are offered as hands-on application training material but can be purchased independently. Training is provided by Innventik’s team of experts with decades of experience in the Rubber and Elastomers domain. To request a copy of the Manuals or information about Training, please get in touch with Dr. Walter Ramirez:

Email: walter@innventik.com

Phone: +34 628859711 (Europe CST)

Electronic Manuals (unlimited users)

The deliverables include a fully illustrated manual’s electronic version (pdf format). The Manuals are delivered after proof of payment is received. Some reports include an Excel database with active links to access individual patents. Available Webinars or in-house Mastercourse format (online or in-house training)

THE CONTENTS OF THE APPLICATION MANUALS:

SBC ADHESIVES FORMULATION FOR PSA, HOT MELT AND SOLVENT BASED.

MODULE 1. INTRODUCTION TO SBC ADHESIVE APPLICATIONS

MODULE 2. COMPONENTS AND ADDITIVES IN ADHESIVE FORMULATIONS

• Base Polymer

• Synthetic Waxes

• Hardener

• Fillers

• Thermal Stabilization (Antioxidants)

• Tackifying Resins

• Plasticizers

• Other Polymers as Additives

MODULE 3. SBC ADHESIVE FORMULATION BASICS

• Recommended Approach to Design Formulations, Engineer, and Qualify Adhesive Formulations.

• Tuning of Properties of SBCs Adhesives:

• Processing & Fabrication of Hot physical blend.

• General Features of Innventik’s SBC Grades.

• Parameters and Specifications for Adhesive Selection.

• Formulation Recommendations and Conventions.

MODULE 4. REFERENCE SBC APPLICATION REQUIREMENTS

• PRESSURE-SENSITIVE TAPES APPLICATIONS.

• GENERAL-PURPOSE PSA TAPES.

• PACKAGING TAPES.

• DUCT TAPES.

• PERSONAL CARE (NON-WOVEN) TAPES.

• ELECTRICAL TAPES.

• PRESSURE-SENSITIVE LABEL APPLICATIONS.

• MASKING TAPES.

• FREEZER LABELS.

• HOLDING TAPES.

• HEAT ACTIVATED LABELS

• REMOVABLE ADHESIVES.

• FOOD PACKAGING

• HOT SEAL AND LAMINATING ADHESIVES.

• COLD SEAL ADHESIVES.

• NON-PSA ASSEMBLY.

• GENERAL-PURPOSE ASSEMBLY.

• BOX CLOSURE.

• BOOKBINDING.

• FOOTWEAR OR SHOEMAKING.

• NON-WOVEN.

• DISPOSABLES.

• BUILDING AND CONSTRUCTION ADHESIVES APPLICATIONS.

• CONTACT ADHESIVES.

• TILE AND FLOORING ADHESIVES.

• ROOFING.

• SUMMARY.

MODULE 5. REFERENCE SBC FORMULATIONS.

GENERAL-PURPOSE SBC FORMULATIONS

• GENERAL-PURPOSE HOT-MELT PSA BASIC FORMULATION (SBS)

• GENERAL-PURPOSE SOLVENT-BASED FORMULATION (SBS)

• GENERAL-PURPOSE SOLVENT-BORNE SEALANT (SBS)

• GENERAL-PURPOSE HOT-MELT PSA (SBS)

• GENERAL-PURPOSE HEAT-ACTIVATED HOT-MELT PSA (SBS)

• GENERAL-PURPOSE HOT-MELT ASSEMBLY ADHESIVE (SBS)

• GENERAL-PURPOSE HEAT LAMINATING ADHESIVE WITHOUT TACK (SBS)

• GENERAL-PURPOSE ASSEMBLY ADHESIVE 1 (SBS)

• GENERAL-PURPOSE ASSEMBLY ADHESIVE 1 (SBS)

• GENERAL-PURPOSE ASSEMBLY ADHESIVE 3 (SBS)

• GENERAL-PURPOSE HOT-MELT PSA MASKING TAPE (SBS)

BOOKBINDING FORMULATIONS.

• BOOKBINDING FORMULATION 1 (SBS)

• BOOKBINDING FORMULATION 2 (SBS)

NON-WOVEN SBC FORMULATIONS.

• NON-WOVEN ADHESIVES BASIC FORMULATION (SBS BASED)

CONTACT ADHESIVES SBC FORMULATIONS.

• GENERAL-PURPOSE CONTACT ADHESIVES W/O REACTIVE RESIN

• GENERAL-PURPOSE CONTACT ADHESIVES WITH REACTIVE RESIN

• TYPICAL TILE AND FLOORING ADHESIVES

FOOTWEAR SBC FORMULATIONS.

• TYPICAL SOLVENT CEMENT FOR POROUS FOOTWEAR 1 (SBS)

• TYPICAL SOLVENT CEMENT FOR POROUS FOOTWEAR 2 (SBS)

OTHER SBC FORMULATIONS.

REFERENCES

POLYMER MODIFICATION MANUAL FOR MASS ABS AND HIPS.

MODULE 1: DESIGN PARAMETERS IN THE SYNTHESIS OF m-ABS & HIPS.

- Types of Process to obtain m-ABS and HIPS.

- Rubber Toughened Plastics Morphology

- Mechanism of Particle Formation and Morphology

- Effect of Graft or Block Copolymer on Morphology

- Impact-Gloss balance with Rubber Particle Size

- Materials Science Concepts of Rubber-Toughened Polymers

- Role of Rubber Type and Characteristics

- Key point

MODULE 2: RUBBER SELECTION CRITERIA FOR m-ABS AND HIPS.

- Rubber Selection Parameters

- Role of Rubber Type and Characteristics

- Typical Rubber Specification for HIPS

- Solution Viscosity Relevance

- Screening rubbers for colors

- Plant Trials

MODULE 3: ROLE OF RUBBER TYPE AND PERFORMANCE.

- Review of Plastics Testing

- Review of Polymerization Process

- Polymer Structure

- Key control PropertiesFactors that control Properties and challenges

MODULE 4: m-ABS AND HIPS PROCESSES & PROPERTIES.

- Main processes

- Comparison of technologies

- Major processing methods

MODULE 5: m-ABS AND HIPS INNOVATION TRENDS AND PATENT ANALYSIS.

- Technology Strategies of major players

- Key parameters to control performance

- Novel processes (HIPS, TIPS, CRP)

- Recent advances in Polymer Modification

- Patent analysis, key technologies, and trends

MODULE 6: IN-SITU POLYMERIZATION KINETICS.

- Polymerization of Styrene in Rubber

- Kinetics and initiators (diradical initiation)

MODULE 7: ANIONIC POLYMERIZATION DESIGN OF LCBR AND SSBR.

- Basic concepts in anionic polymerization

- Types of solvents

- Controlling Molecular weight and distribution

- Block Copolymers

- Radial Polymers

- Functionalization

MODULE 8: STRUCTURE OF LITHIUM INITIATORS.

- Structure of alkyl-lithium initiators

- Initiation and propagation

MODULE 9: MOLECULAR WEIGHT AND MWD.

- Methods

- Styrene-Butadiene Copolymers analysis

MODULE 10: MICROSTRUCTURE OF POLYDIENES.

- Microstructure and characterization

- Addition of Lewis Basis

- Polar Modifiers

- Coupling Agents

- Poisons

- Copolymerization control

MODULE 11: RUBBER BLENDS FOR m-ABS & HIPS

- BR and SSBR Blends cases

- Key points

MODULE 12: MECHANICAL BLENDING APPROACHES

- Rheology of miscible blends

- Comparative Morphologies

- Results of mechanical blending (blend and graft types)

- Properties of the matrix

MODULE 13: KEY INFORMATION FROM MARKET, CUSTOMERS, USERS

- Designing new products based on unmet needs

Differentiation ideas

MODULE 14: MARKET INSIGHTS FOR ABS & HIPS

- General market overview of ABS

- General market overview of Polystyrene

POLYMER COMPATIBILIZATION MANUAL FOR SBCs BLENDS AND ALLOYS.

MODULE 1: COMPATIBILIZATION BASICS

• Basic Definitions

• Effect of Compatibility on Properties

• Failure and Causes in Multi-Phase Polymer Systems

• Effect of various Parameters on Compatibility

• Morphology of Multiphase Polymer systems

• How to Increase compatibility in Blends and Composites

• Real World Examples

MODULE 2: BLENDS, ALLOYS, COMPOSITES.

Section 1. Specific Methods to increase and optimize the compatibilization with Polyolefins

Section 2. Polyolefin Based Alloys, Blends, and Composites.

Section 3. Strategies for various combinations with Polylefins.

Section 4. Real World Applied Examples: Developing Superior Polyolefin based alloys, blends and Composites

Section 5. New Developments in Compatibilized Polyolefin-Based Alloys, Blends and Composites

Section 6. Styrenic Resin Blends.

MODULE 3. MARKET SEGMENTATION.

• Tier, 1 Applications

• Tier 2 Applications

• Tier 3 Applications

MODULE 4. POLYMER COMPATIBILIZATION FOR BLENDS AND ALLOYS.

ABS, HIPS, PET, Nylon, PC, Acrylics, PP, High Styrene Resin, PU, Polysulfones, Polyphenylene Oxide, PE, and ABS/Nylon, PP/Nylon, Nanocomposites, PPO/PPE.

(Main function for the compatibilizer, Formulations, Competing products-Technologies, End Users-Compounders-Final End User, Technology/performance limitation, Met/unmet needs, Identify if segment uses PB/SBC/SIS, Competitors)

MODULE 5. STRATEGIC ANALYSIS.

• Penetration Strategies

• Conclusión

SSBR-F FUNCTIONALIZATION FOR HIGH PERFORMANCE TIRES MANUAL.

MODULE 1. BASIC CONCEPTS, MARKET, DRIVERS.

• Main Drivers

• SSBR and SSBR-F Generations

• Technologies for SSBR Functionalization

• Market Drivers: Regulations and Labeling Initiatives

• Market Drivers: LV OE & Replacement Tire Demand

• Synthetic Rubber Market Overview: Tires Overview

• SSBR and SSBR-F Market Overview

• Global SSBR Capacities (2023)

• SSBR Production Capacities

• SBR Market Price Overview (China, Dec. 2023)

• SSBR Rubber Supply-Demand

• SSBR-F Market Insights

• Key Points: Tire Trends Toward Sustainability using SSBR-F

MODULE 2. INTRODUCTION: SSBR HIGH-PERFORMANCE TIRES.

• Tire Manufacturers unmet Needs & Issues

• Tire Manufacturers Regulations and Labeling System

• High Performance Tires (HPT) Basic Concepts, Polymer Overview

Types

• Styrene-Vinyl Balance and High Performance

• Solution SBR (SSBR) vs. Emulsion SBR (ESBR)

• Rolling Resistance Basic Concepts

• Reinforcing Nanofillers, Coupling Agents and Silanes

• Branching

• Morphology and Viscoelastic Properties

• Rubber Additives for HPT: Rheology Modifiers

• Rubber Additives for HPT: Liquid Rubbers

• Rubber Additives for HPT: Pre-dispersed Carbon Black

• Rubber Additives for HPT: Elastomer Nanocomposites

• Sustainable Biomonomers: Bio-Butadiene

• Conclusion & Remarks: SSBR for HPT and UHP Tires

• Technological Trends Summary

MODULE 3. SSBR-F Functionalization Strategies.

• Challenges for Optimum Rubber Dispersion

• Basic Functionalization Approaches Overview

• Alfa-Omega Chain-End or Terminal Functionalization

Strategies

• Along the Chain Functionalization Strategies

• Multifunctional Polymers

• Protection and Deprotection of Functionalized Groups

• Metallation Functionalization Reactions

• Other Approaches for Functionalization Overview

• Conclusion on Functionalization Strategies

MODULE 4. SSBR-F RELEVANT TECHNOLOGIES.

• Overview: Annual Geographic Filing Strategy

• Overview: Key Technology Focus (IPC)

• Overview: Most Relevant Patents

• Overview: IP strategy Radar Map

• Overview: Top 20 Tire Makers

• Overview: ClUster Cell Diagram, Landscape Map, Timeline

• Overview: Relevant SSBR & SSBR-F Commercial Grades

• Conclusion SSBR-F Relevant Technologies and Companies

MODULE 5. MAIN COMPANIES.

Company Insights. Main Products. Key Technologies. Patent Analysis.

TRINSEO.

MICHELIN.

BRIDGESTONE.

CONTINENTAL.

GOODYEAR.

ARLANXEO.

JSR-ENEOS.

ASAHI-KASEI.

NIPPON ZEON.

SUMITOMO.

TSRC.

VERSALIS.

KUMHO.

MODULE 5. FINAL REMARKS AND REFERENCES.

REFERENCES.

PATENT DATA BASE SSBR-F 2024 (EXCEL)